tekWorx can help your team go beyond analytics to optimize the efficiency of your dynamic system. We understand that true optimization requires automated action, not manual tweaks.

Analytics packages seem to have it all. At first glance, integrated dashboards provide a snapshot of operational processes, metrics and key performance metrics (KPIs).

Unfortunately, analytics as an actual cost reduction tool in chilled water systems are limited unless a human takes action on this information to adjust operations. Optimizing the efficiency of dynamic systems, such as a chilled water plant requires action, ideally continuous action, that does not rely on manual intervention.

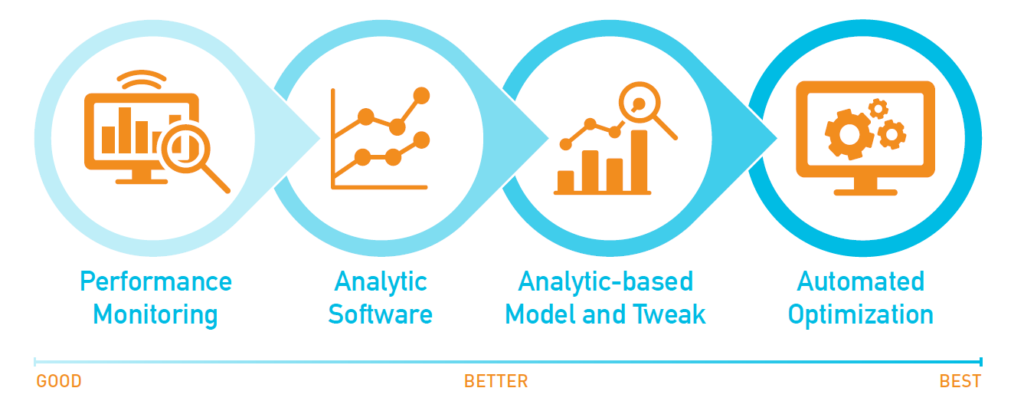

The optimization spectrum

The various levels of efficiency improvements

Of the four basic levels of efficiency improvements in use today, optimization and analytics are the most discussed. While they are complementary, they are not the same. Analytic and model-based strategies simply suggest edits, not action. Without automation, analytic software cannot optimize dynamic settings like a chilled water plant.

tekWorx automated optimization

The Approachable Experts™ at tekWorx can help your team go beyond analytics to optimize the efficiency of your dynamic system.

Our automated optimization solutions maximize the use of your existing mechanical equipment and controls to significantly improve plant performance. Using adaptive algorithms to continuously analyze real-time process variables, key control parameters are automatically adjusted to minimize plant kW/ton without any human intervention.

For more details and insight in the differences between chilled water plant efficiency improvement models, download our latest white paper, “Go Beyond Analytics to Optimization in Chilled Water Systems.