Proven Chiller Plant Optimization Solutions

What We Do

Optimize cooling production and permanently cut energy bills

tekWorx team of Approachable Experts ® design, install, and optimize real-time efficiency solutions for your chiller plant’s specific needs. These adaptive solutions cut annual energy costs and water use up to 50%.

How We’re Different

Approachable Expertise ®

Straightforward Process

- No recurring fees

- No black box

Complete Flexibility

- Any BAS, any chiller make/model

- Any protocol

On-site Execution

- Continuous real-time adaptive technology

- Remote diagnostics optional

Comprehensive Solutions

- Airside and waterside

- Mechanical, controls, and operations

Trusted by

Irvine, CA

Pharmaceutical Plant Optimization Saves $542,000, Earns $250,00 Utility Rebate

White Papers

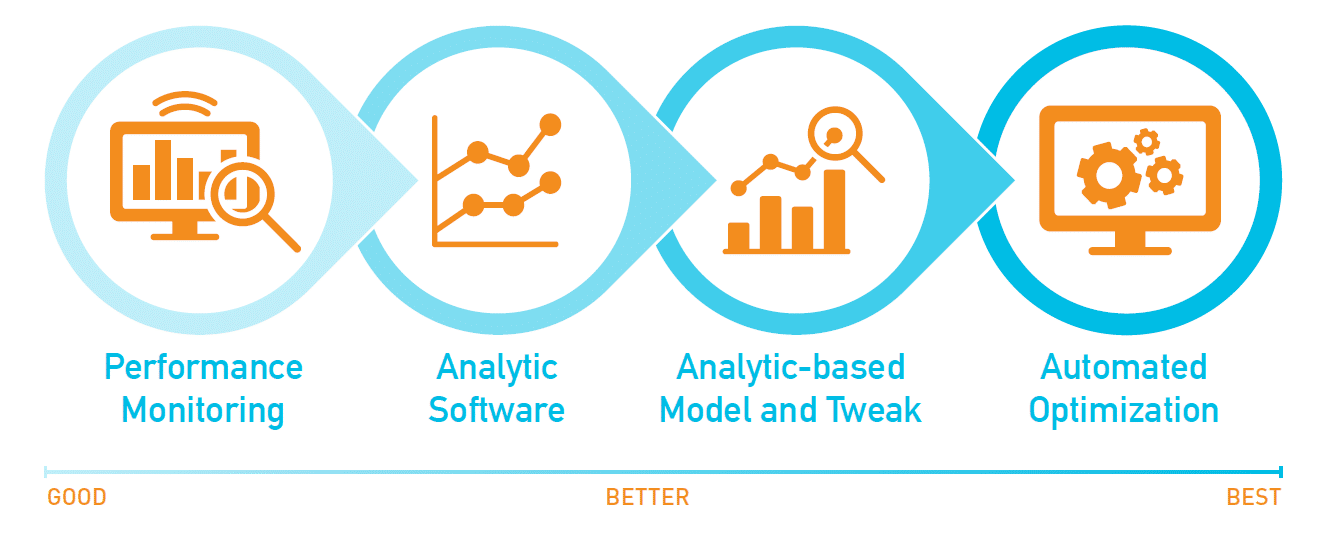

Analytics Is NOT Optimization

Chilled water system optimization requires actual process changes, not just suggestions or ‘actionable intelligence’. Read our latest white paper for more insights on the various tiers of optimization.